WOHT

Table of contents:

Product description

Axial, high-temperature, medium-pressure fans designed for the high-temperature drying process in installations where high dust and larger elements of solids contained in the flowing air can damage the motor. The fan bodies, hot-dip galvanised, are fitted with a chamber that effectively isolates the motor from the air stream. They are ideally suited for use in modern grain dryers where emphasis is placed on high drying parameters with a recuperation process. Designed for continuous operation at high temperatures, i.e. up to + 105°C.

- Standard diameter range: Ø800 – Ø1000mm

- Capacity range: 20000 – 50400m3/h

- Operating temperatures: -20 to +105°C

- Installed motor powers: 5.5 – 22.0 kW

- Motor speeds: 1500 min-1

- Motors fitted with maintenance-free bearings

- Motors adapted as standard for speed control by a frequency converter

- Steel housings

- Corrosion-protected housing – hot-dip galvanised

Optional executions

- High-temperature temp. max: 135°C (WOHT)

- Enclosure made of stainless steel

- Flow parameters other than standard

Construction

Housing

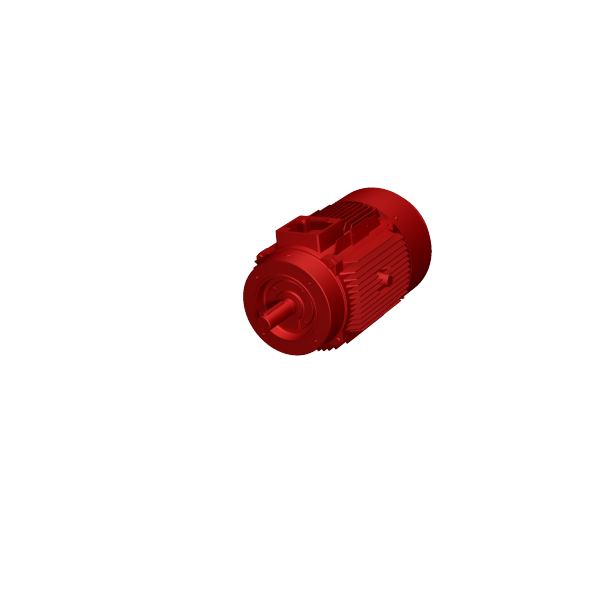

Motor

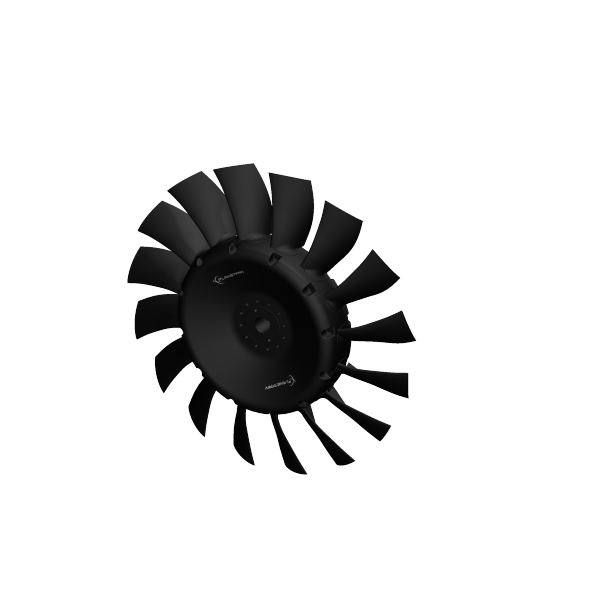

Rotor

Housing:

- Perfectly round, machined from structural steel sheet. Equipped on both sides with flanges rolled from the casing shell with connection openings

- Equipped with a separate motor compartment

- Equipped with a rear guide

- Protected against corrosion by hot-dip galvanising

Housing optional:

- Corrosion protection by powder coating

- Housing made of stainless steel, grade 1.4301

- Inspection hatch

- Painted in another RAL colour

Motor:

- Asynchronous 3 phase

- Supply voltage: 3~ 230/400V; 400/690V

- Efficiency class : IE3

- Insulation class: F

- Degree of protection: IP 55

- Cast aluminium or cast iron motor body

Motor optional execution:

- Supply voltage: 440V, 460V

- Supply frequency: 60Hz

- Efficiency class: IE 4

- Motor insulation class: H

- Degree of protection: IP 56, IP66,

- Winding temperature sensors

Impeller:

- Blades and hub made of die-cast aluminium

- High-performance blades with special sickle shape for lower noise levels

- Lower energy consumption while maintaining high pressures

- Dynamically balanced to class G-6.3 according to ISO 1940-1