WOAG

Table of contents:

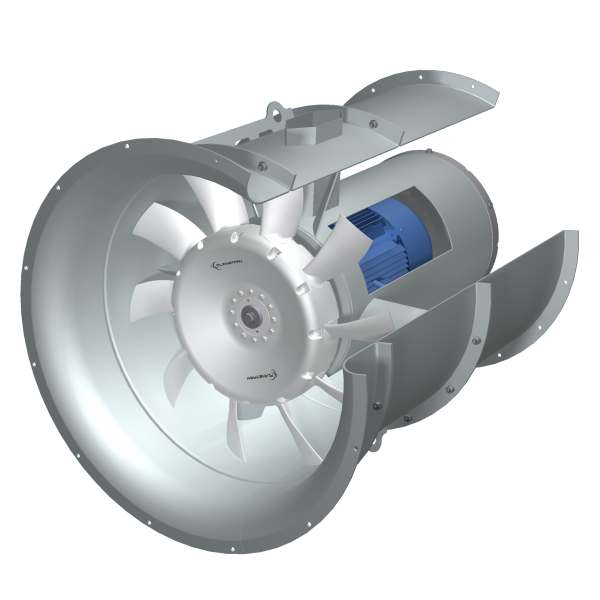

Product description

Medium-pressure axial fans designed for the drying process in installations where high dust levels and larger elements of solids contained in the flowing air can damage the motor. The fan bodies, are equipped with a chamber that effectively isolates the motor from the air stream. The shaped impeller blades, made of aluminium, generate higher pressures and are more resistant to operation in adverse conditions. They are used in modern grain dryers.

- Standard diameter range: Ø800 – 1000mm

- Capacity range: 20000 – 50400m3/h

- Operating temperatures: -20 to +70°C

- Installed motor powers: 5.5 – 22.0 kW

- Motor speeds: 1500 min-1

- Motors fitted with maintenance-free bearings

- Motors adapted as standard for speed control by a frequency converter

- Steel housings

- Corrosion-protected housing – hot-dip galvanised

Optional executions

- Explosion-proof

- High temperature temperature max: 105°C (WOHT)

- Enclosure made of stainless steel

- Flow parameters other than standard

Construction

Housing

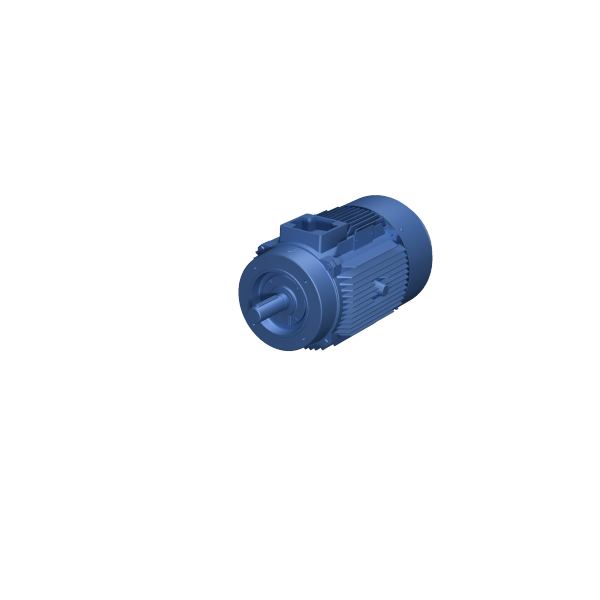

Motor

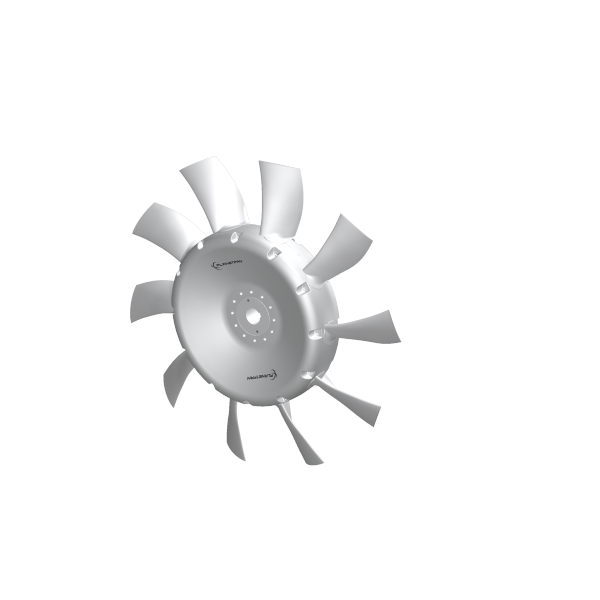

Rotor

Housing:

- Perfectly round, machined from structural steel sheet. Equipped on both sides with flanges rolled from the casing shell having connection holes.

- Equipped with a separate motor compartment

- Equipped with rear guide vane

- Protected against corrosion by hot-dip galvanising

Housing optional:

- Corrosion protection by powder coating

- Housing made of stainless steel, grade 1.4301

- Inspection hatch

- Painted in another RAL colour

Motor:

- Asynchronous 3 phase

- Supply voltage: 3~ 230/400V; 400/690V

- Efficiency class : IE3

- Insulation class: F

- Degree of protection: IP 55

- Cast aluminium or cast iron motor body

Motor optional execution:

- Supply voltage: 440V, 460V

- Supply frequency: 60Hz

- Efficiency class: IE 4

- Motor insulation class: H

- Degree of protection: IP 56, IP66

- Winding temperature sensors

Impeller:

- Blades and hub made of die-cast aluminium

- High-performance blades with special sickle shape for lower noise levels

- Lower energy consumption while maintaining high pressures

- Dynamically balanced to class G-6.3 according to ISO 1940-1